介紹中空玻璃打膠機怎么操作�!

關(guān)于中空玻璃主動(dòng)打膠機小編現已和我們說(shuō)了很多�����,比如關(guān)于職業(yè)額發(fā)展����、整體的現狀��,還有和中空玻璃相關(guān)職業(yè)的知識等等�?�?墒切【幇l(fā)現很多的讀者在私信小編時(shí)問(wèn)的都是有關(guān)于中空玻璃主動(dòng)打膠機的根底操作等相關(guān)問(wèn)題�����。今天小編就和我們清清楚楚的說(shuō)清楚關(guān)于中空玻璃主動(dòng)打膠機的調整與操作的問(wèn)題�。

We have talked a lot about the small edition of the active gluing machine for hollow glass, such as the professional development, the overall status quo, as well as the knowledge of hollow glass related professions and so on. However, Xiaobian found that many readers in private trust Xiaobian asked about the basic operation of the hollow glass active gluing machine and other related issues. Today, Xiaobian and we clearly explained the adjustment and operation of the active gluing machine for hollow glass.

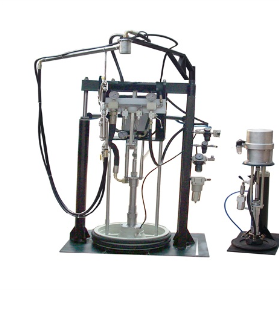

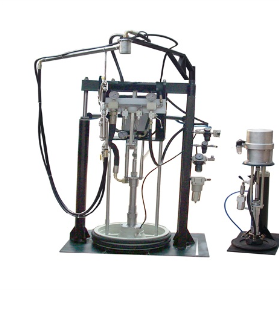

中空玻璃主動(dòng)打膠機

Hollow glass active glue machine

操作流程:

Operation procedure:

1��、 放在一個(gè)平整潔凈的平面上�����,連接電源和氣源�����,兩者承認接通之后就開(kāi)始進(jìn)行操作�����。

1. Place it on a flat and clean surface, connect the power supply and the air source, both of which admit to start operation after the connection.

2�、 打膠機中間會(huì )有一個(gè)混膠過(guò)程���,在供膠機上面混膠完畢之后����,需要在電子顯示屏上控制面板上進(jìn)行挑選“行走設置”�����。翻開(kāi)界面之后按T1鍵前進(jìn)行走���。在機頭中止時(shí)���,翻開(kāi)機頭上面B膠閥門(mén)�,接著(zhù)在控制面板上找到Esc鍵回來(lái)主界面�,然后F2狀態(tài)設置�����,在翻開(kāi)界面后按K3鍵供膠開(kāi)始�����,當膠嘴中完全混合的膠流出按K4鍵完畢供膠�����。

2. There will be a mixing process in the middle of the glue beater. After mixing is finished on the glue feeder, it is necessary to select "walking settings" on the control panel of the electronic display screen. After opening the interface, press T1 button to move forward. When the nose stops, turn on the B glue valve above the nose, then find the Esc key on the control panel to return to the main interface, then set F2 status, press K3 key to start gluing after opening the interface, and press K4 key to finish gluing when the completely mixed glue in the nozzle flows out.

3����、 需要記住的是工作完畢之后或者在較長(cháng)時(shí)間不工作時(shí)�,需要沖洗混膠裝置���,避免供膠管的阻塞����,影響未來(lái)運用作用���。

3. It should be remembered that after the completion of the work or after a long period of non-work, it is necessary to flush the mixing device to avoid the obstruction of the rubber supply pipe, which will affect the future application.

4�、 調整環(huán)節:吸盤(pán)調整:涂膠機吸盤(pán)與旋轉臺的高度調整合適�。

4, adjustment link: sucker adjustment: the height adjustment of the suction machine and the rotary table of the glue dispenser is suitable.

5�、 氣動(dòng)開(kāi)關(guān)����、膠嘴����、探針調整:將事前合好的中空玻璃放在旋轉臺上���,靠近涂膠機工作面�,然后中空玻璃推到定位上����,調整膠嘴與玻璃的高度��,使出膠嘴的出膠口中心于鋁槽中心在同一個(gè)水平線(xiàn)上:膠嘴與玻璃之間的頂力合適:鋁槽深度檢測探針與出膠口中心線(xiàn)在統一水平線(xiàn)上�。

5. Pneumatic switch, glue nozzle and probe adjustment: place the hollow glass on the rotary table, close to the working face of the glue coating machine, then push the hollow glass to the position, adjust the height of the glue nozzle and the glass, so that the glue outlet center of the glue nozzle is on the same horizontal line at the center of the aluminium groove: the top force between the glue nozzle and the glass is appropriate. The depth probe of aluminum groove and the center line of the rubber outlet are at the same level.

6��、 發(fā)動(dòng)開(kāi)關(guān)(機頭的前端的光開(kāi)關(guān))與玻璃之間的檢測間隔(1.5~2mm)���。在控制面板上挑選“狀態(tài)設置”���,翻開(kāi)狀態(tài)設置后挑選“吸盤(pán)開(kāi)(K5鍵)”�����,此時(shí)機頭會(huì )往前移動(dòng)�����,假如不往前移動(dòng)則檢查并調整發(fā)動(dòng)開(kāi)關(guān)的檢測間隔��。

6, the detection interval (1.5~2mm) between the starting switch (the optical switch at the front end of the nose) and the glass. Select "state setting" on the control panel and "sucker opening" (K5 key) after turning on the state setting. At this time, the nose will move forward. If it does not move forward, check and adjust the detection interval of the start switch.

上一篇:自動(dòng)打膠機和手動(dòng)打膠機的區別有哪些����?

下一篇:教你灌膠機的保養方法�����!